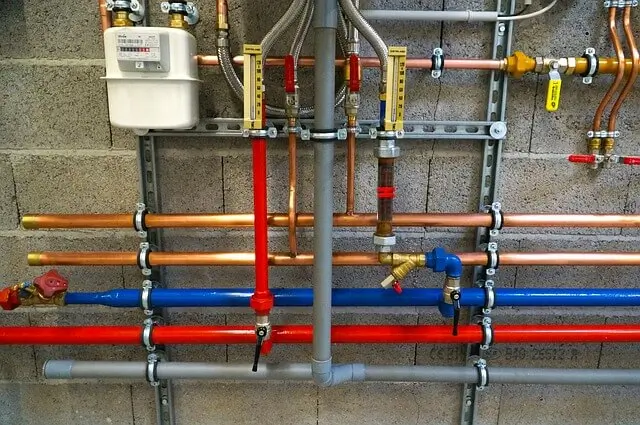

If you’ve ever tried plumbing repairs, then you might know how hard it could be to install copper, galvanized steel or PVC pipes. But installing PEX pipes is fast and easy since they’re flexible, durable and lightweight. PEX pipes are, therefore, ideal for piping projects such as electrical wiring insulation, domestic water supply piping, and heating/cooling pipework systems. To successfully and effectively install PEX pipes, you will need the right tools and special work input. One of the tools that you will need is the PEX crimp tool. As such, you should arm yourself with this tool and know how to use before beginning the PEX pipe installations.

How does the PEX crimp tool work?

The PEX crimp tool not only simplifies PEX pipes installations but also saves your time. And working with this tool is also very simple. You can follow this guide to know how to use your tool in the simplest and easiest way.

Just follow our steps below to use your tool in the simplest and easiest way.

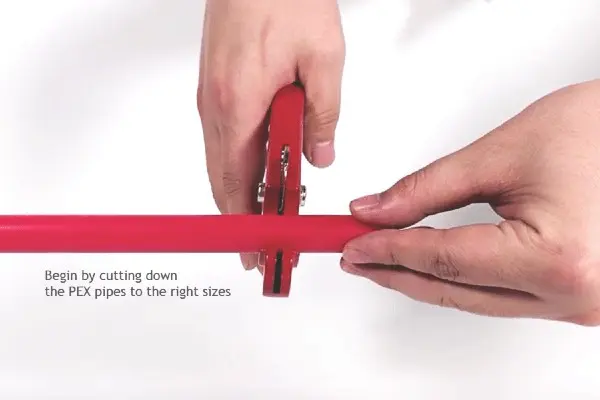

Cutting down the PEX pipes to the right sizes with PEX Cutter Tool.

With a PEX cutter tool, cut down squarely your PEX pipe(s) to the right sizes, step 1 becomes very easy.

And understanding the color-coding of the pipes is important. PEX pipes come in three different colors red, blue, and white. The red pipes are for hot water, blue pipes are for cold water and white ones are neutral pipes. That means you can either connect them to hot or cold water.

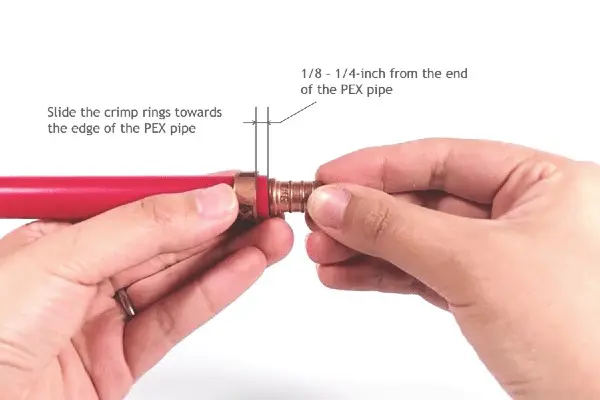

Take the PEX crimp ring or PEX clamp ring and slide them over the ends of the pipes.

You should slide the rings one at a time! At the end of step 2, your PEX pipe will have rings over both of its ends. Then go ahead to step 3 below.

Insert the PEX fittings into the ends of the PEX pipes.

Push the PEX fittings into the opening of the PEX pipe. Again, you will push the fittings one at a time. Even if you are using the 90 degree elbow fittings, push them through the openings of the pipe.

Slide the rings towards the edge of the PEX pipe.

Drag the rings closer to the fittings that are already in place. Normally drag them so they’re 1/8 – 1/4-inch from the end of the PEX pipe.

Take out your PEX crimp tool and open it.

Pull the handles of the PEX crimp tool apart to open it. This will create an opening on the tool. Fit the opening on the tool into the crimp/clamp ring.

Shut the tool by pulling its handles back together.

The PEX crimp tool will pop and apply pressure on the PEX crimp ring thus creating a watertight seal.

You are almost done here, only one more step for sure.

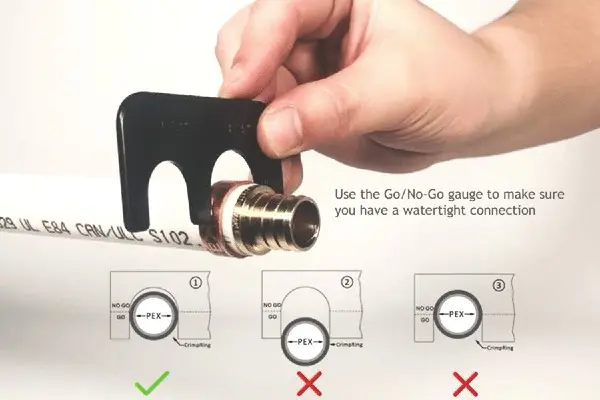

Use the Go/No-Go gauge to check your seal.

To make sure that you have a watertight seal at this point. Slide the Go slot of the gauge over the PEX crimp ring. If the GO slot fits on the ring, then you have a watertight seal.

To confirm if you have an excellent seal, use the No-Go slot as well. If the ring doesn’t fit on the No-Go slot, you have a watertight seal or perfect connection.

Congratulation!

Now you are ready to start your plumbing project. Let’s come and choose for yourself a best PEX crimp tool: https://forhandyman.com/best-pex-crimp-tool/

Alternatively, you can use SharkBite fittings to make super-watertight connections with PEX or copper pipes. Simply push the PEX or copper pipe into this type of fitting and you will be all set. But first, you will need to put the PEX pipe into a SharkBite depth tool.

Then, use a marker to mark the end of the SharkBite depth tool. That’s when you will simply slide the PEX pipe into the SharkBite fitting until the fitting meets up the mark. The only downside of SharkBite fittings is that they’re pricey.

Some FAQs

What’s the difference between the PEX crimp tool vs PEX clamp tool?

If you look at these two types of tools, you will notice some differences. First, the PEX crimp tools work only with copper crimp rings. On the other hand, PEX clamp tools work with both copper and stainless-steel clamp rings. More detail about the difference you can read on this article:

Can you remove PEX fittings?

Yes. First, cut off the ear of the clamp(s) with a wire cutter. Then pry the remaining portion of the clamp with a flatbed screwdriver. Once you have completely removed the ring or clamp, pull out the fitting(s) with less effort. Just see this video for sure.

Between clamp and crimp, which method is better?

PEX crimp and PEX clamp are two popular methods for connecting PEX fittings to PEX piping in plumbing and heating systems. The PEX crimp tool involves crimping a copper ring onto the fitting and piping, creating a permanent and secure connection. The PEX clamp tool, on the other hand, involves clamping a stainless steel clamp onto the fitting and piping, creating a secure connection that can be easily undone if needed.

In terms of strength and durability, the PEX crimp connection is considered to be stronger and more secure, as the crimping process compresses the copper ring onto the fitting and piping. The PEX clamp connection is considered to be more versatile, as the clamping process is easily reversible if needed.

The installation process for PEX crimp and PEX clamp also differs. The crimping process requires the use of a separate copper ring, while the clamping process does not. The crimping process is considered to be more time-consuming and requires more specialized materials, while the clamping process is considered to be quicker and more straightforward.

In terms of cost, the PEX crimp tool and components are typically more expensive than the PEX clamp tool and components. The crimping process requires specialized materials such as copper rings, while the clamping process uses more readily available stainless steel clamps.

Conclusion

Having the best PEX crimp tool at hand is ideal if you’re installing PEX. Carefully select your tool since some inferior models exist on the market. PEX crimp tools tightly secure the crimp ring on the PEX pipe in place. The result is a watertight connection that will leave no room for water leaks.

Besides, these tools are easy to use and have unmatched durability. They will, therefore, serve you for years to come. Also, you will need this tool for future PEX installations. This tool deserves to be in your tools store. It comes in handy for DIY plumbing.

After knowing how to use PEX crimp tool, installing the PEX pipes should now be a piece of cake.

References: How to Install PEX at Instructables.com